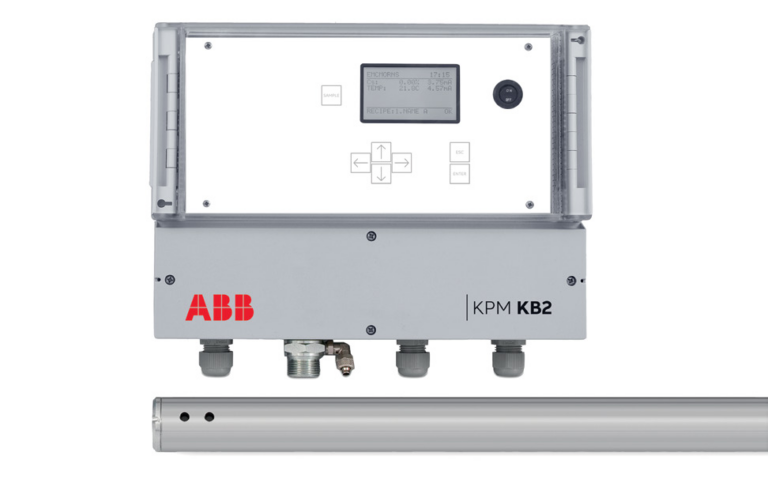

KPM KC5 Rotating Consistency Transmitter

Revolutionary Direct Drive Servo Motor

The KPM KC5 Rotating Consistency Transmitter requires no compromising. With excellent consistency measurement performance, light weight construction, simple installation, and dramatically reduced maintenance, KPM KC5 is the most advanced consistency transmitter in the market.

Fast and accurate measurement

Through ABB’s state-of-the-art torque measurement technology the KPM KC5 provides an accurate consistency measurement–instantly. Our sensitive, wide-range measurement sensor is applicable to all consistencies between 1.5-16 percent. Built-in temperature compensation assures performance in all process conditions.

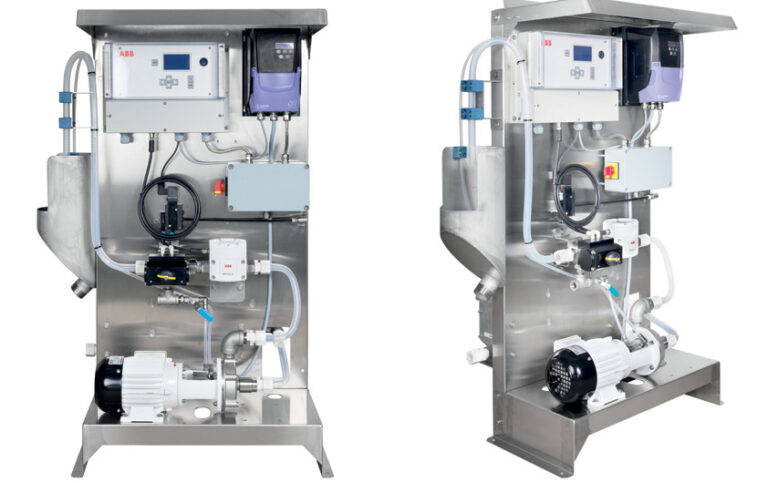

Low installation costs

KPM KC5 is easy to install. Replace your existing model rotary transmitter with KPM KC5 using our special adapter to fit your current rotary installation. For new installations, use the measurement chamber that is provided with the transmitter. All required hardware is included.

No shutdown required

Built-in gate valve assembly allows you to extract transmitter on the fly, at full process pressure, without having to shut down or drain the line. Flange installation is also available as an alternate option.

Dramatically reduced maintenance

With no drive belt to change, the Direct Drive Servo Motor rarely requires routine maintenance. Our unique mechanical seal system enables enables infrequent, low-cost maintenance. Simply replace the seals, on site, in an hour or less.

Powerful self-diagnostics

Automatic maintenance features include reverse direction rotation to automatically loosen foreign objects. Calibration verification with Autozero is possible while the KPM KC5 is operating in the line.

Our Partners

T5 Group is a solution-centered and partner-focused company with over 15 years of experience. We have been a dedicated resource for maintenance, reliability, implementation services, and support for customers across the United States.