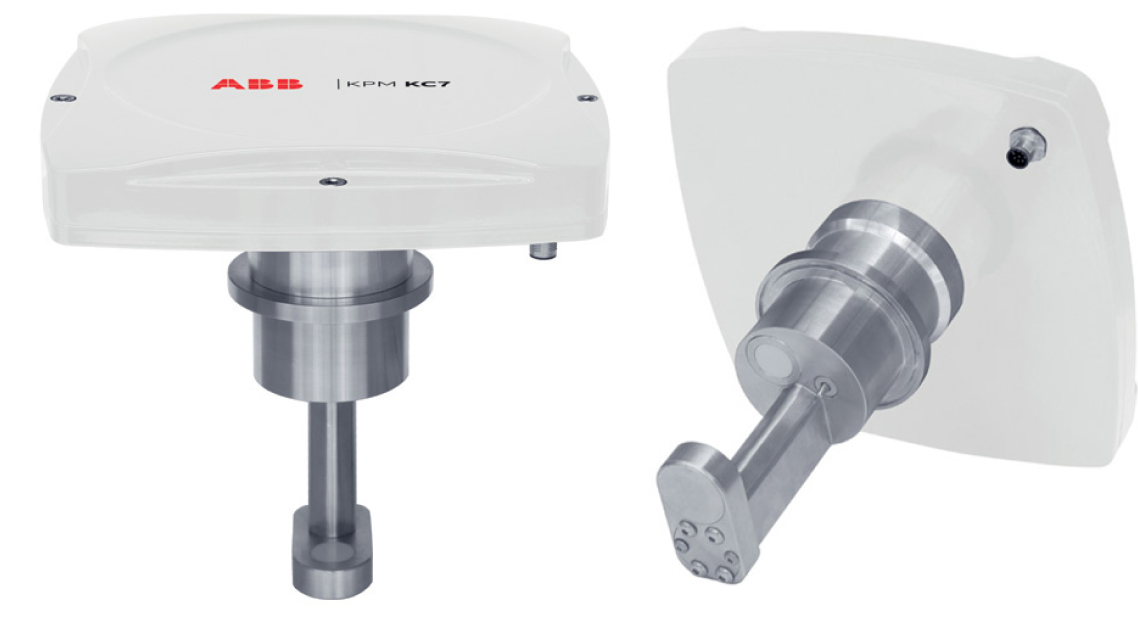

KPM KC7 Microwave Consistency Transmitter

T5 GROUP SOLUTION CENTERED KPM KC7 Microwave Consistency Transmitter

T5 GROUP SOLUTION CENTERED KPM KC7 Microwave Consistency Transmitter

KPM KC3 provides reliable and maintenance-free measurement. With its patented, shock resistant and seal-less transfer mechanism, KPM KC3 is the only transmitter in the market with no moving parts. It also boasts titanium parts for the wetted areas and an unbreakable diaphragm to stop process from entering transmitter.

KPM KC3 fits all applications, measuring a consistency range of 2-16 percent. Plus, the unique and highly-sensitive eddy probe accurately measures shear force.

Remote display unit can be mounted to any desirable location. It has a large display and intuitive, menu-driven user interface, which features simple set-up, calibration and troubleshooting functions.

One-touch calibration sequencing makes sampling, set-up and calibration easy. Built-in features include: time-stamping of samples for later evaluation and calibration, calibration calculation with multiple points and statistics, and remote selections for different pulp grades.

The installation is done via standard stainless steel mounting saddles, with titanium options available for upgrade. Service requirements are low because of the seal-less transfer mechanism with no moving parts or O-rings. All parts are field changeable without shutting down the process and emptying the process line.

Sensor type

Blade consistency transmitter

Output signal

2 -wire, 4 – 20 mA + HART®,

Foundation Fieldbus and Profibus PA with optional converter

Measuring range

2 – 8% with standard blade

6 – 16% with medium consistency blade

2 – 3% with low consistency blade 2 – 8% with recycled unscreened blade

Sensitivity

Better than 0.01 % Cs

Process pressure

Max. 25 bar

Process temperature

0 – 120 °C

Ambient temperature

0 – 65 °C

Storage temperature

-50…+80 °C

Flow velocity

0.5 – 5 m/s (1.6 – 16 ft/s) standard blade

0.5 – 5 m/s (1.6 – 16 ft/s) medium consistency blade

0.5 – 5 m/s (1.6 – 16 ft/s) low consistency blade

0.5 – 5 m/s (1.6 – 16 ft/s) recycled unscreened blade

Weight

Transmitter 2.3 kg (5 lbs), Display unit 2.2 kg (4.9 lbs)

Process connection

Clamp connection to NS70 mounting saddle. Saddle welded onto process pipe. All required hardware included with the transmitter.

Process pipe size

100 mm (4“) diameter or larger

Materials

All wetted parts titanium or Stainless steel. Mounting gaskets PTFE, Mounting saddle SS316L, SMO, Duplex, Titanium or FRP

Low voltage & emc

IEC 6100-4-3 and CISPR 11

Enclosure class

Sensor unit IP 66 (better than NEMA 4X), Display unit IP65 (NEMA 4X)

Damping

1 – 99 sec.

Calibration

Memory for 10 samples (FIFO). Built-in calibrator.

Build in curves

Seven (7) built-in calibration curves for softwood, hardwood, TMP, CTMP, groundwood, recycled, eucalyptus + one (1) user specific.

Binary inputs

Three (3) to select calibration curve and one (1) for sample button.