KRA and KRT Retention Measurement

T5 GROUP SOLUTION CENTERED KRA and KRT Retention Measurement

T5 GROUP SOLUTION CENTERED KRA and KRT Retention Measurement

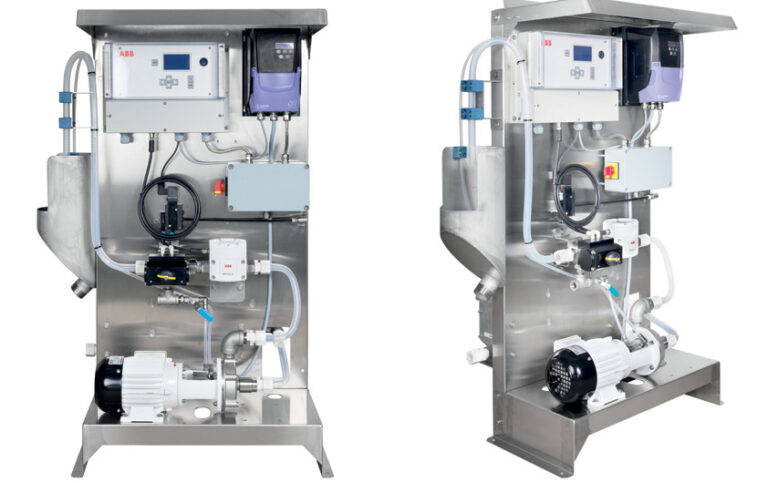

Retention control is important to papermakers due to the large influence it has on paper quality variability reduction. ABB’s ultimate solution for monitoring and control of paper or board machine retention is KPM KRA and KRT Retention Measurement

ABB offers two options for paper and board machine retention monitoring and control: the KPM KRA sensor measures total consistency and ash consistency, while the KPM KRT sensor is for total consistency only. The measurement range for total consistency is 0-2.0 percent Cs and 0-1.0 percent for ash consistency.

The sensor is constructed of 316SS with an unbreakable stainless steel measurement cell, enabling the sensors to withstand harsh environments. The display unit and sensor have protection class of IP65 (Nema 4X) and do not need protective housing to withstand difficult conditions at the paper machine wet end.

Automatic flushing with water can be included to keep the sensors clean without maintenance. The optical sensor has a 3 mm gap between the lenses, which produces a self-cleaning effect due to the increased velocity. The white water sensor also has self-cleaning due to an automatic backflushing module.

Sensor type

Retention sensor with optical consistency transmitter

Measurement range

KPM KRT – Total Consistency 0 – 2.0%, minimum 0.005%, 50 ppm

KPM KRA – Total Consistency 0 – 2.0%, minimum 0.005%, 50 ppm

KPM KRA – Ash Consistency 0 – 1.0%, minimum 0.005%, 50 ppm.

Process temperature

10 – 60 °C (50 – 140 °F)

Process pressure

Max 10 bar (140 psi)

Sample flow rate

Minimum 10 l/min (2.5 gpm)

Process connection

Sample valve, diameter 21,3 mm with 3/4” tube connector

Sample line

Fluorinated ethylene propylene (FEP) recommended; max 4 bar (58 psi)

Output signals

3 × 4–20 mA, active, consistency, ash consistency (KPM KRA) and temperature

Binary inputs

4, closing dry contact, process stop, grade change (2), sampler input

Binary output

1 x closing or opening dry contact for general alarm.

Power requirements

Headbox sensor: 90-264 VAC 50/60+3 Hz; 20 VA

White water sensor: 100-115 VAC or 200-240VAC, 50/60+2 Hz; 800 VA

Ambient temperature

0 – 50°C (32 – 122°F)

Flushing water

Mechanically or chemically purified, temperature 25-60 °C (77-140°F)

Same as sample or max 20°C (68°F) warmer,

Pressure 2–6 bar (30–90 psi)

Sealing water

Needed when sample pump included

Same water will be used for flushing when pump included

Instrument air

Pressure 4 – 8 bar (60 – 120 psi), oil-free

Interconnect cable

From sensor to display unit, Included automatically, 1,0-2,0 meters

Sensor materials

Wetted metal parts AISI 316, Wetted tubing FEP

Conformance

73/23/EEC, 89/336/EEC, EN 61000-6-4:2001, EN 61000-6-2:2001,

EN 61010-1:2001

Enclosure class

IP 65 (Nema 4x)

Dimensions (L x W x H)

Dimensions: 380 x 765 x 1170 mm (15 x 30 x 46″)

WW sensor in inch: (20 x 30 x 46″)

Weight

Headbox sensor 26 kg (57 lbs) White water sensor 48 kg (106 lbs)